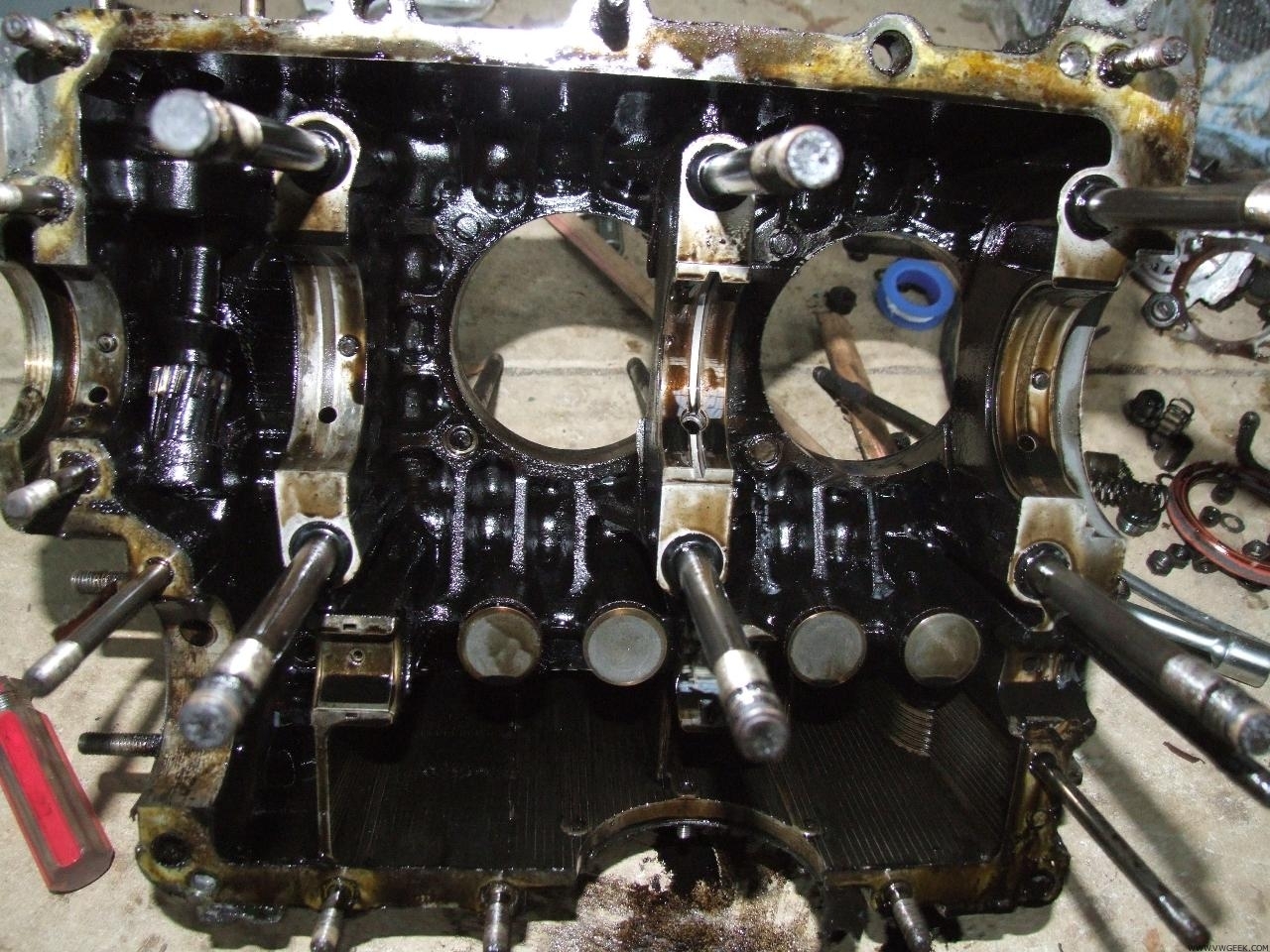

Welcome once again another quick update on the progress of the beetle, As you may have seen previously I pulled the body off the pan and now have a chance to check the pan after some fun water had gotten under the stock tar stuff and surface rusted the pan.

There she is sortof rusted but really its only skin deep, I went out and grabbed some rust converter from Bunnings pricey but well worth its weight in gold.

That’s about 30 minutes after i put the first lot of rust converter on, its fairly simple you rough the rust up then paint this on.

That’s the other side after the first coat dried and converted overnight looking pretty shmick, you can also see the great patch job done by my father on the holes bade from the battery acid.

After the second coat, its just awesome (please note the stuff in the pictures that now looks like rust is red dust/dirt from those thatch rear seats.

Now a lot of people would be like wtf is this red stuff (and other are what idiots don’t know what this red stuff is) Its red oxide, i actually used it on some problem spots on the bottom of one of the beetles doors and even though it still got wet etc i haven’t seen one spot of rust since. My father who was a boilermaker welder swearers by it as well. This is the first coat, there have been a few more coats since then and the seat rails have been painted black.

More pics and updates on this when I get back up the farm and have a chance to take some more pics.