I will copy the post i posted on the vwar.org forums.

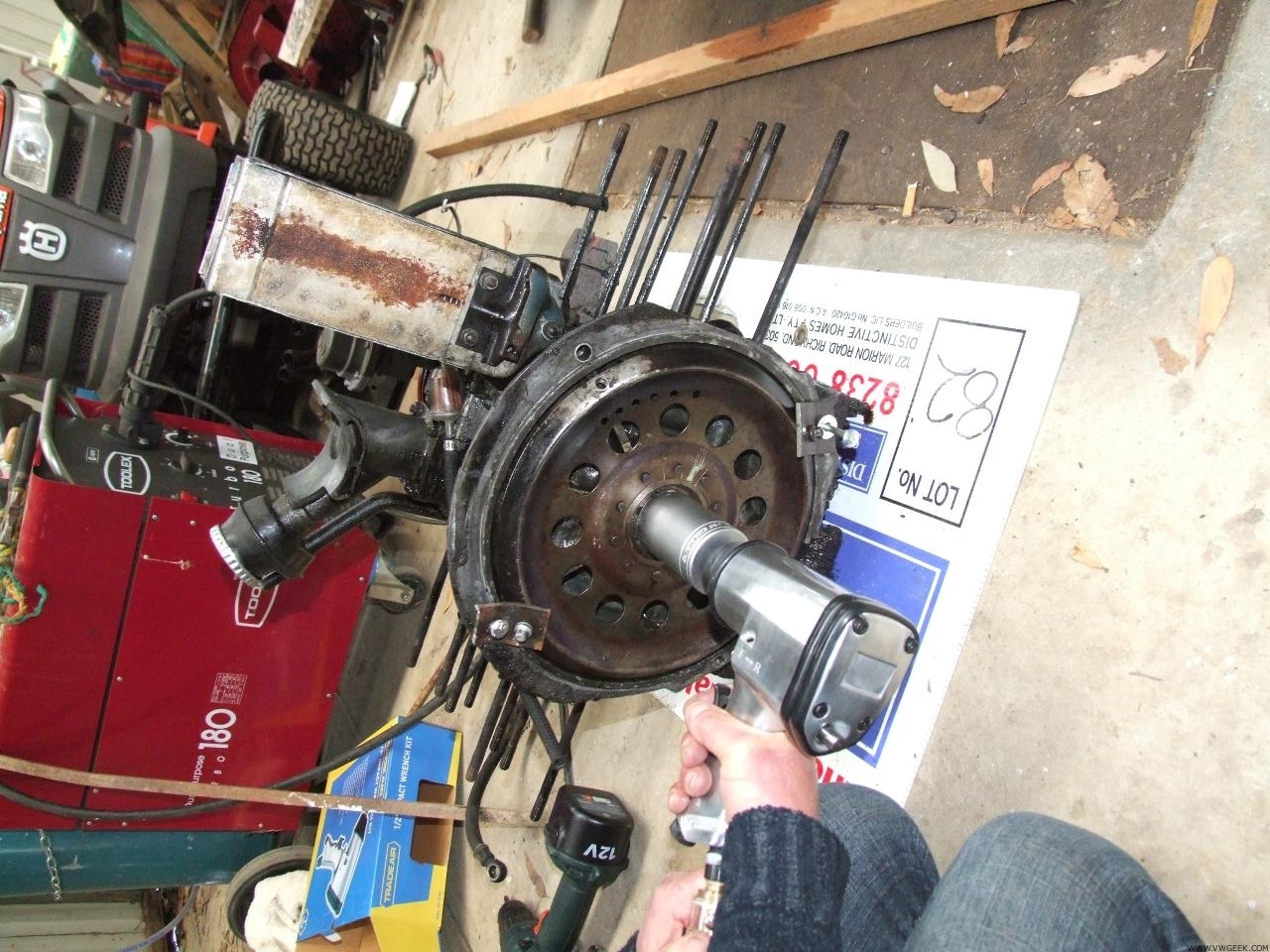

I removed the motor from an auto stick today. It went well (as in I got the motor out) and bad (as in I now have a removable rear valance)

Okies well there I was watching and reading the diy guides on motor removal, but it looked fairly simple and as the Bentley hadn’t arrived I decided to ump on in.

With guidance from 68autobug and a few others on the vwar.org forum I jumped in.

Now I will go from start to finish (as I was a complete amateur at this)

First we undo the accelerator cable from the carbie and push it into the tinware (and out the back)

Next undo any pipes that are leading from the control valve to the carbie. Also you will notice a pipe coming out the front bit of the tinware that has a bolt on it BE very careful if you bend this your rooted, use two spanners to do it and a heck of a-lot of WD40.

Now go for a scoot under the car (drain the oil), find where the accelerator cable is and pull it out (I found that I needed someone to jiggle the other side of the cable to find it)

There is also a fuel line down there so undo it and chuck a screw driver in the end to stop it leaking (I still got petrol all over me).

There is also 1 pipe that leads to the control valve just undo it from the valve itself and pull it through (not sure if this is really needed)

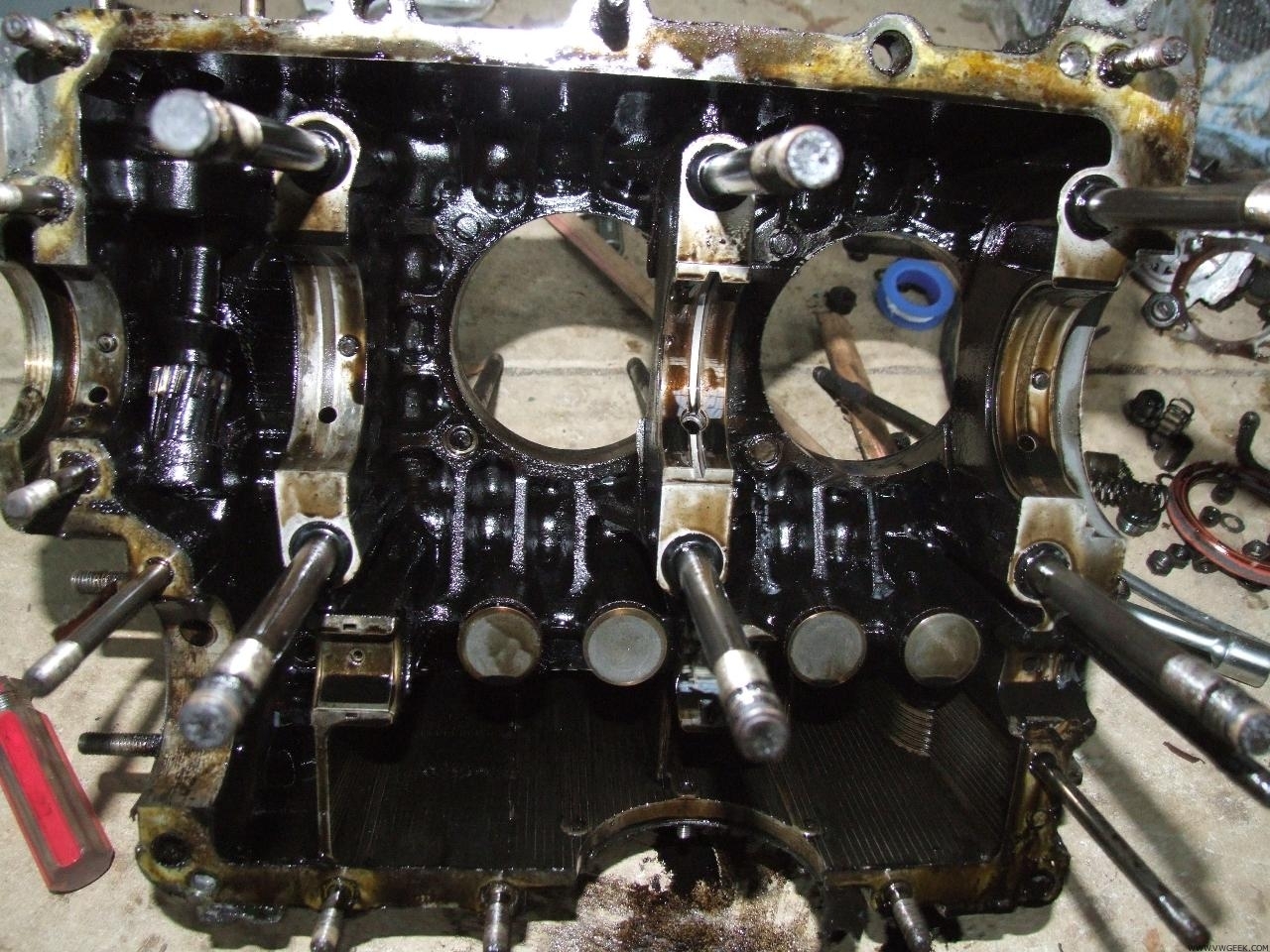

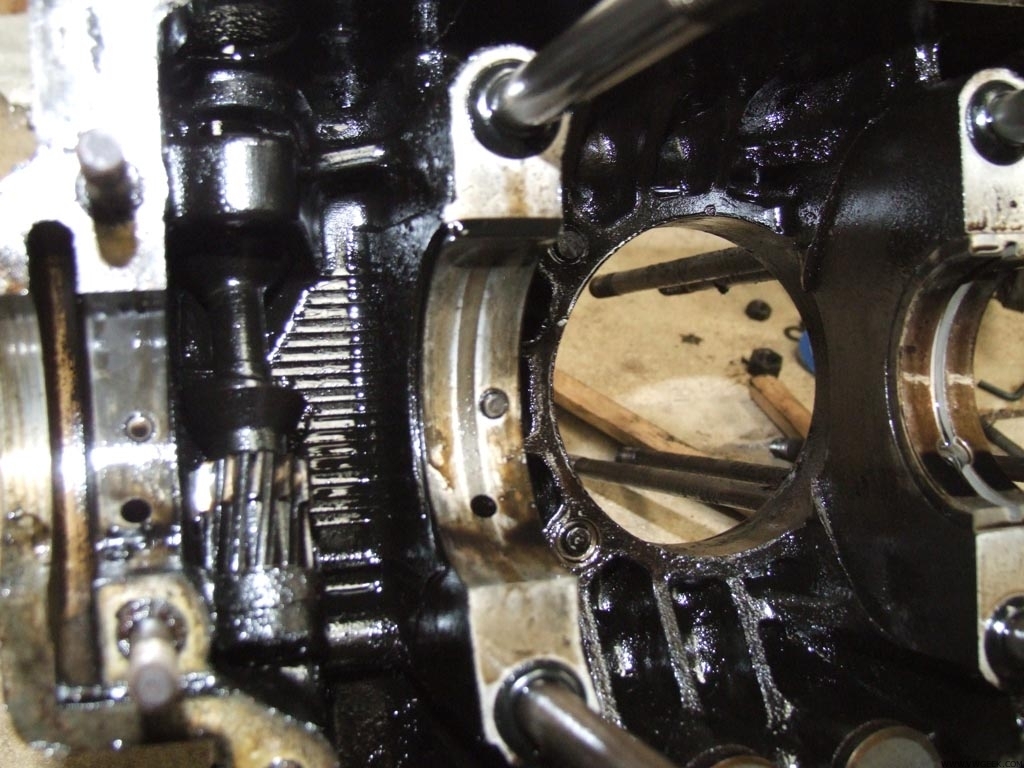

Being a 1600DP motor that means its the normal dog house fan shroud. So I remove the first bolt on the top behind the shroud (RHS)

Next one was a so called “easy” one to get to, I reckon I spent the good part of two hours here, the bolt which would be easy to get to on a standard manual was now obscured by the clutch armature (tank) {that may be the wrong description}. You could reach the bolt here but I just couldn’t seem to get enough leverage on the bolt to undo (you know how ratchet and extensions can be) it. Anyway I ended up grabbing my trusty 10mm ratchet and taking the 3 bolts that hold the tank in, out. Then its held with a tube clip to the armature I just closed it and popped the connector out. Now I could remove the tank and get to the bolt and use some strength to undo it (I almost had a hernia here).

The following bolt is like directly below the first bolt (10 or so cms), nice and easy and the final bolt is on the other side in the same identical spot to the previous.

I then undid the lot of 4 bolts that I believe affix the torque converter, they are directly below the last two screws and easy to get to. (this is WRONG)

By now you more then likely need a shower and a nice big eye rinse (I was black lol)

So were at the spot where we drop the motor.. all the books said just pull the tail pipes with a jack under the oil strainer and she will disengage.. Which is what I did sure it came out, but I physically couldn’t get the motor forward enough to pull out, then I realised my aftermarket exhaust was stoping the movement of the engine, I undid the exhaust and gave it a go.. damn still cant get the motor out far enough for the teeth on the torque converter to clear, (now seeing the torque converter isn’t meant to happen it turns out there are 4 8mm/10mm bolts that connect the torque converter to the flex plate, to reach them you need to go under the car {before you take the motor out} and undo the 4 screws through the access holes on the side of the transmission housing). So here I am motor half out torque converter teeth grinding on the transmission housing, and every move I’m getting worried this motor removal could be terminal.

I remembered a quick post I here about the car needing to be level (as the backend was just jacked up) it didn’t seem to make much difference.

I just sat there defeated by what is supposedly the basic of basic motor removals. I thought screw it I ground the rear apron off and the motor came out beautifully. (with the thoughts of making it into a removable apron later.)

I replacement aprons a few days back for $40 each brand new, you think I could find some in stock after I cut the apron off????.

So yeah oops but then again makes life easier with a removeable apron in the future.

What i thought i would post here is the greatest thing ever. I was chatting on the aussieveedubbers.com forums about an engine trolly,and i went seatching high and low but they wanted upwards of 150 bux for one and for something i may only use 2 or 3 times. (thanks to Matt Ryanfrom Aussieveedubbers for finding this pic at Obsolete Air-Cooled Documentation Project.

Notch Nutfrom Aussieveedubbers let me in on a secret shopping trolleys make the best motor dollies. The story here is amazing, I seriously read this post and thought but how the heck could i get a trolly i don’t live near any supermarkets and i don’t know of any compulsive shopping trolly hoarders near by. Anyway to the good part a few days after notch nuts post i was driving near coles and i was saying to my partner “i really need just the trolly base” and believe it or not there is this beauty sitting in the middle of the road no basket to be seen, i opened my boot threw her in and was on my way, sometimes you just have to be lucky.

And that’s basically how it works.

and there she is in use 😀 works a treat, thanks guys.